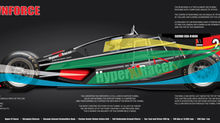

Half-Time Mock-Up

We have made a lot of the components for the X1 and we decided to sticky-tape the parts together to see what our baby looks like. Larger...

How to build a wing.

Like all the composite parts on the X1, the process of making a part is a 4 step procedure. 1. Design 2. Pattern 3. Mould - soon 4. Part...

Bodywork progress

Work is progressing on the bodywork. GROUND EFFECTS For 50 years racing cars have utilised wings (inverted airfoils) to increase the...